How Industrial Air Conditioning Brazing Works? Brazing is defined as joining two components together at a temperature of over 800 degrees Fahrenheit. The temperature threshold must be met for the brazing to be successful.

The bonding material used to join air conditioning parts is known as sil-phos. The higher the content of silver in the sil-phos the higher the quality of the compound.

Table of Contents

Six Steps for Air Conditioning Brazing Works

The Industrial Air Conditioning Industry has established 6 basic steps to braze air conditioning parts successfully. These steps follow a specific order to complete the process.

Closely, follow these six Industrial Air Conditioning Brazing Work steps to braze Industrial air conditioning parts together:

1. Critical Fit with Proper Clearance

Brazing air conditioning parts together requires the parts to fit properly giving the proper clearance before the parts are permanently joined. If the clearance is not the proper distance and the parts don’t fit precisely once joined the job becomes complicated.

The ideal clearance range for two parts to be joined are between .001-.003 and not greater than .005. If two parts fall within the ideal range then the whole Brazing Air Conditioning Brazing Works process flows smoothly.

Also, if the clearance is less than .001 the molten filling material will not flow through the joint. If the clearance is greater than .005, or .006 then the filling compound may not fill the joint completely. There is a fine line to achieve the proper clearance between the two joined parts.

Fitting

The next part of the step is to establish the proper fitting of the tubes together in the brazing process. If the tubes fit are copper to copper then the heat expansion of the two separate copper openings will be equal.

The tubes are copper to stainless steel, for example, then the expansion heating rates will be different. To solve a potential misfit ting between the two tubes follows these guidelines:

If the heating process will reduce the clearance between the two tubes (because of different materials being joined) then allow for a loose clearance of .010. If the heating causes expanding the clearance between the tubes then allow for tighter clearance before the parts are heated.

2. Clean the Metals

For the filling to adhere to two joining surfaces together they must be clean and free of all foreign substances. The surfaces have oil, grease, or dirt on them the filler will not bind the two parts together. Clean oily or greasy surfaces with a solvent, if the surfaces are oxidized clean them with an emery cloth. Join the two surfaces together immediately after cleaning them. Why? Delay the joining of two surfaces and they will become contaminated again.

3. Flux the Parts

Flux, a chemical compound, will be either a liquid or paste. It is applied to a joint surface before brazing occurs. Flux will protect surfaces from oxidizing and the flux will soak up any oxides and it will help the alloy to flow properly.

Flux does not always have to be applied before brazing. If the two surfaces are copper to copper then flux is not needed. But a phosphorous filler must be used instead. If the two surfaces are of different composition (copper to steel) then flux must be applied.

Flux may be applied by brush or applied directly into the filler material with a flux rod or flux-coated wire.

4. Put together for Brazing

This is a critical step in the Industrial Air Conditioning Brazing Works process. The actual heating and brazing process cannot be done without this step. The two parts must be lined up and supported for proper brazing to take place.

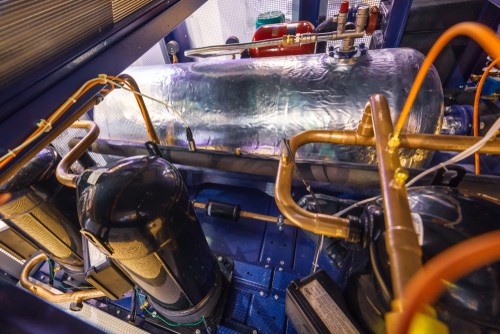

Industrial air conditioning parts are designed to align and support once inserted together. The parts brazed together are tubular-shaped. Assemble the two parts by fully placing one part within the other part for proper sealing and connecting in the brazing process.

5. Complete the Brazing Process

Heat both parts evenly to cover both surfaces. The filler metal must be wet proportionately on both part surfaces. The best heating tool to use is a gas torch. Once the two parts have reached the proper heating temperature now apply the filler joint material.

Sweep over the joint one more time with a soft flame.

6. The Final Cleaning

Now, the brazing process is complete. Clean the joint one final time with a scolding water wash. Swabbing or brushing will accomplish the cleaning process. If there are residue stains use a wire brush to remove them.

How Industrial Air Conditioning Brazing Works – Conclusion

Finally, follow these basic steps for effective Industrial Air Conditioning Brazing Works. The process will flow smoothly every time.